News

- Production technology...

- How to analyze the same ...

- Introduction to conical ...

- The advantages of twin...

- The characteristics and ...

- Characteristics of...

- Characteristics of...

Hot Product

PP/PE line

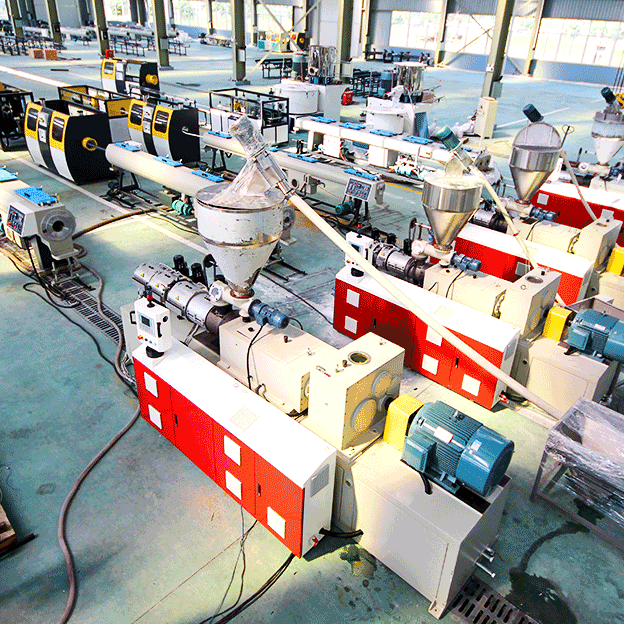

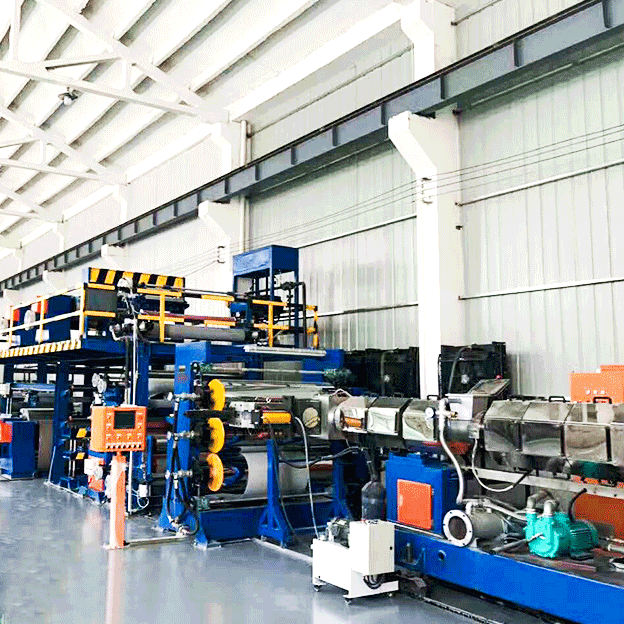

Our company developed the same conical twin-screw extruder (PE / PP board dedicated), using the European first talk with the same cone double technology, the product combines the cone-shaped twin-screw extrusion pressure and parallel With the building block-type twin-screw plastic mixing advantages, is the current domestic and foreign PE / PP board manufacturers the best choice!

- Product Details

-

At present, the domestic PE and PP board extrusion are generally used single screw extruder to 170 single screw, for example, its main motor power of 185-250KW, extrusion output of about 600-700KG / H, Consumption of up to 300 degrees, I developed the company with the same cone-shaped twin-screw extruder (PE / PP board dedicated), using the European first talk with the taper cone technology, the product combines the cone-shaped double-screw Of the extrusion pressure and parallel to the same building block twin-screw plastic mixing advantages, but also absorb the advantages of single-screw extruder extrusion pressure stability is the current domestic and foreign PE / PP board manufacturers the best choice!

Our 75-type co-rotating conical twin-screw extruder and the 80-screw extruder production, we will be the energy of these two devices to do the actual test:

1) power: single screw extruder power consumption of more than 150 degrees per hour, I developed the same company with the tapered twin screw extruder only 120 times per hour, the actual power saving 30 degrees per hour;

2) the material is strong: I developed the company with the same cone-shaped twin-screw extruder can be processed PE / PP particles, calcium powder filler, recovery of broken materials.

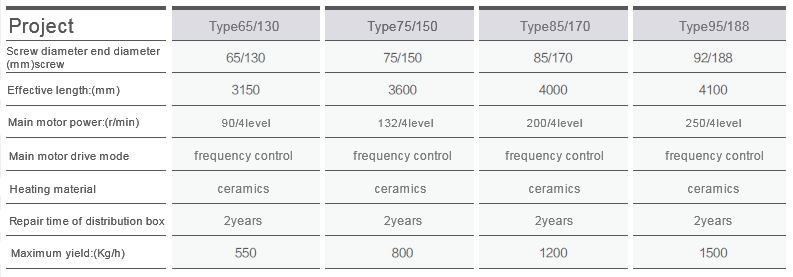

Specifications